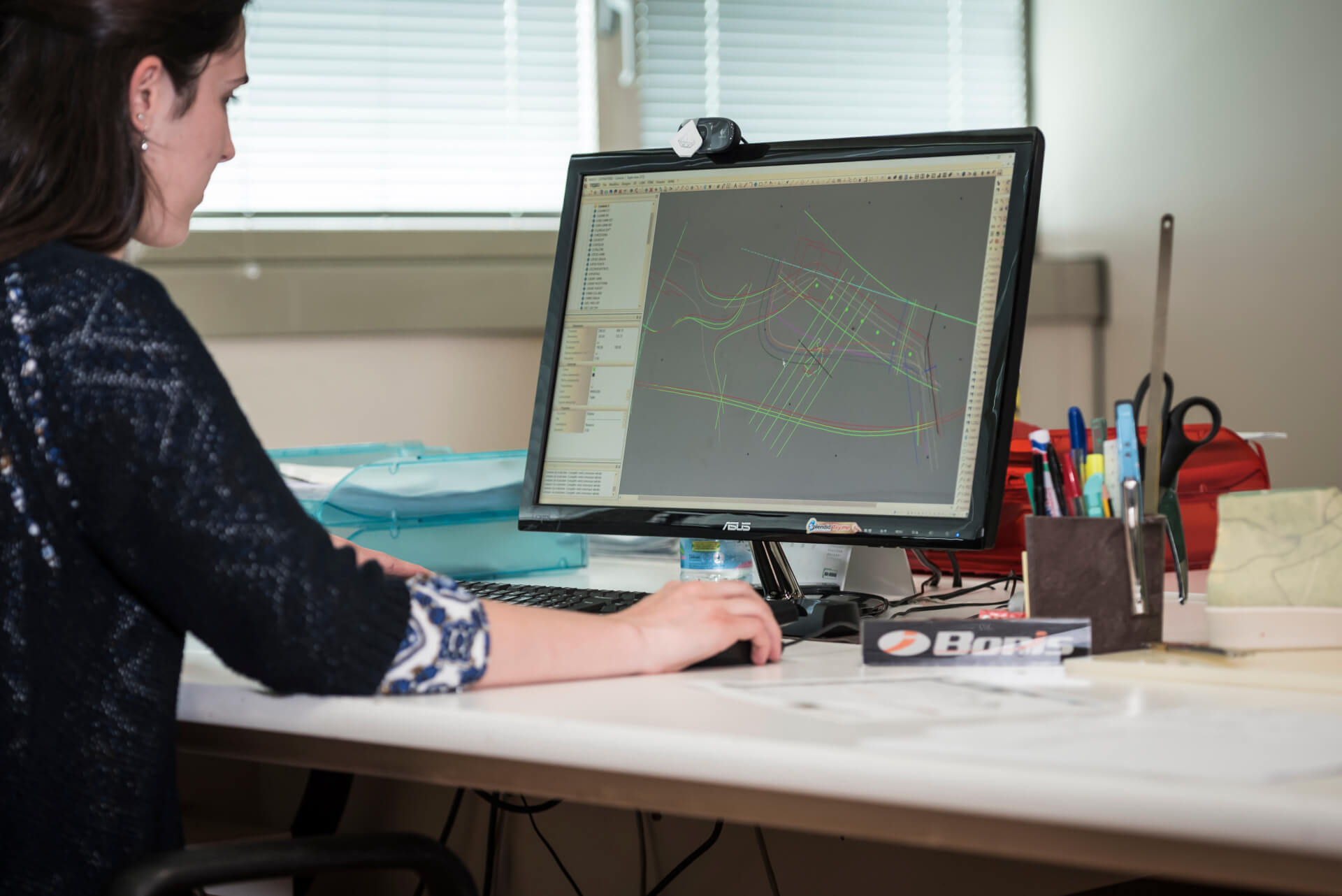

Creation of exclusive collections for each individual client.

Models are presented both as digital renders and as physical prototypes, accompanied by a mood board to illustrate the tone and style of the collection.

Proposal of new materials, sole mockups and colour swatches.

Identification of components in response to the clients’ needs in terms of look, technical specification and price point.

Testing of all materials, whether commercial or developed in-house, to ensure compliance with the physical, mechanical and chemical requisites of European regulations.

Availability of a wide range of tested and certified components for the production of waterproof and motorcycle protective footwear (EN 13634:2015).

Development of sizes for the entire range.

In-house testing for fitting and fit, and design validation.

Production of test lots and verification of production engineering and project quality standards.

Production at our factories, with around 500 employees and a capacity of 500,000 pairs a year.

Multi-year collaboration in joint ventures with European and Asian factories which satisfy our project and quality standards, supported on site by BON-Lab® laboratory technicians on placement.

Physical, mechanical and chemical testing aligned with our quality standards and compliant with European regulations.

Routing tests pursuant to EN 13634:2015 for the materials used in our motorcycle protective footwear.

Quality control at every step of the production process.

QC reports on the finished product conforming with the standards specified by the company checklist.

Packaging and labelling.

Finished product shipping from Bonis to the client’s warehouse.

Option of partial or custom shipping to the client’s requirements.